SPECIAL WELDING HEADS

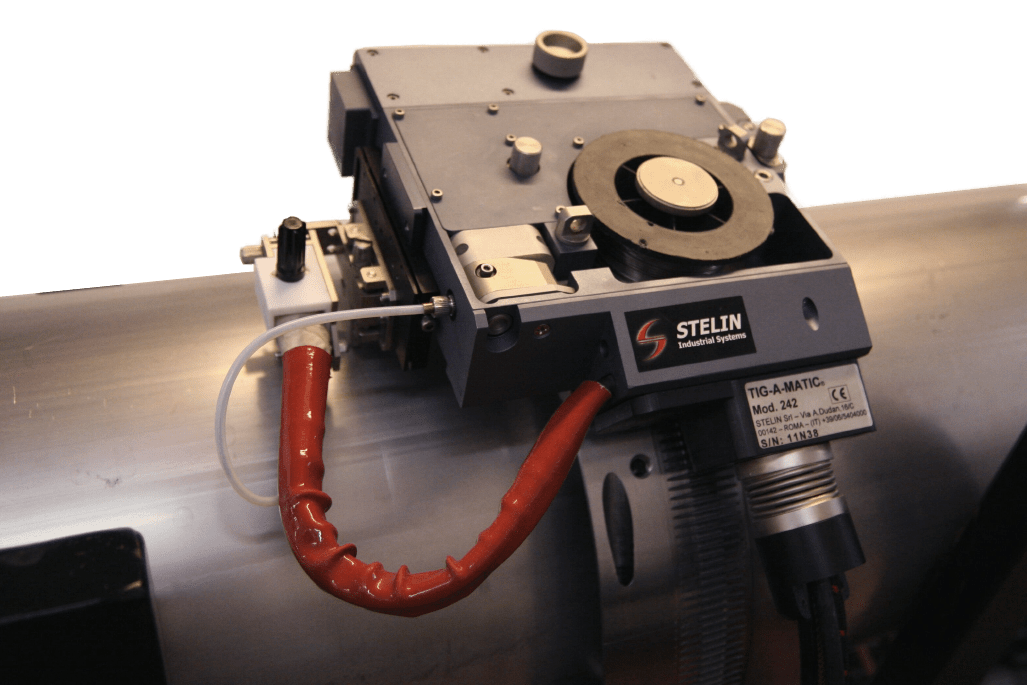

Mod. 242

FOR TUBES OF LARGE DIAMETER

Model 242 can weld tubes of external diameter range from 6” up to 36” standard.

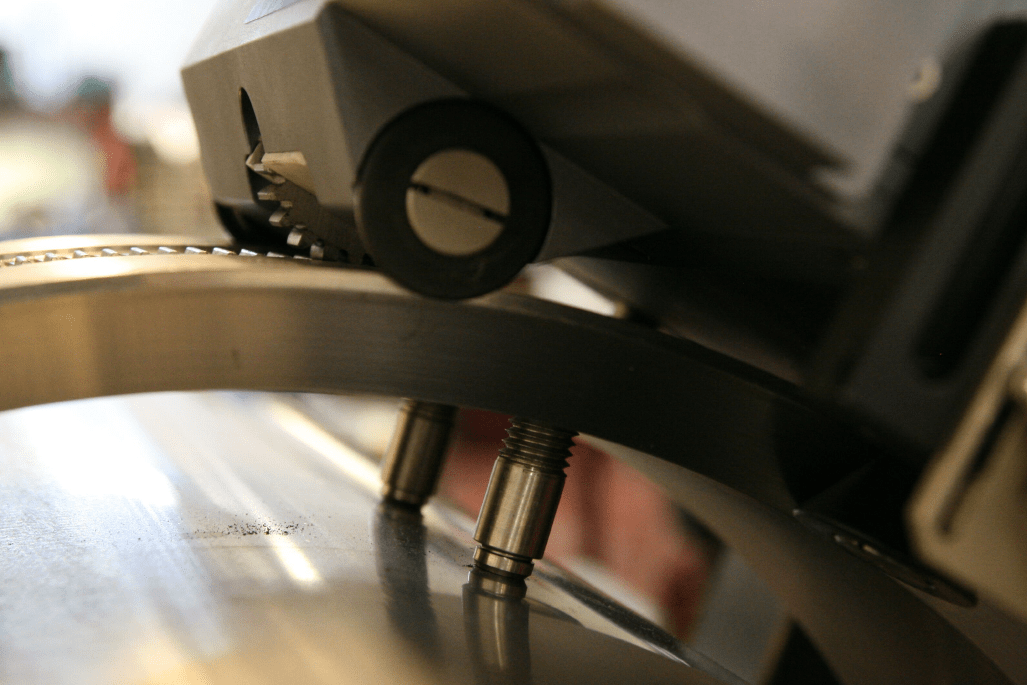

Equipped with AVC and torch Oscillation systems. The filler wire feeding unit and the rotation motor unit are assembled inside the weld head.

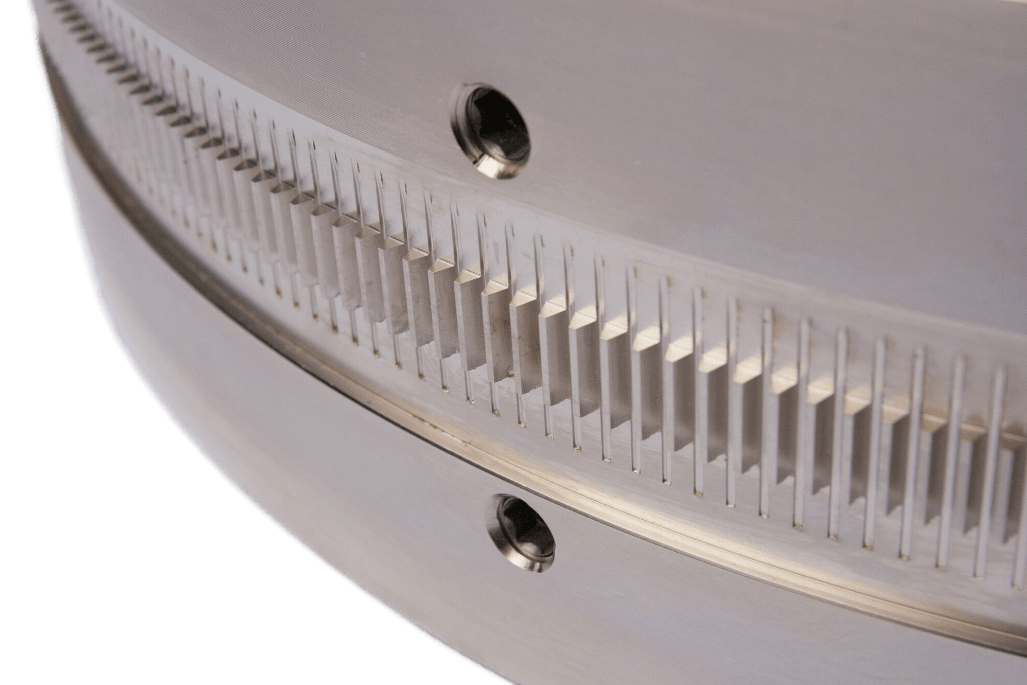

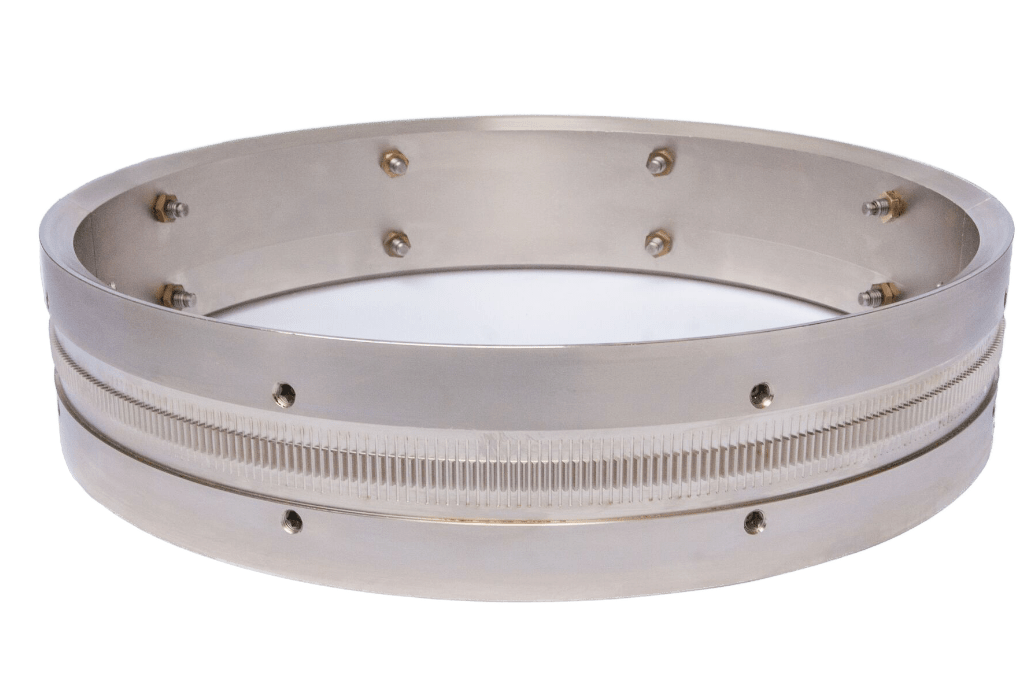

Blocked on the rails in fast and easy way.

Rail guides are particularly light. Their assembling and disassembling is a simple and rapid process due to the clamping mechanism which eliminates any difficult blockage and contemporaneously assures the centring of the rail guides.

Water cooled torch is easy to service and disassemble. The wide AVC and Oscillation range is limited (up and down) by an electronic security system.

PRODUCT TECHNICAL SHEET

Welding procedure: TIG and TIG welding with filler wire

Welding position: Horizontal / vertical / inclined

Welding diameter: Min.: 6″ – Max.: Plane

Welding current: Max. 250 A 100% ED

Torch cooling: Water cooled

Gas down-flow: By gas lens and ceramic nozzle

AVC and torch Oscillation speed: Max. 300 mm/min

Machine rotation speed: Up to 469,3 mm/min

Filler wire speed: Max. 200 cm/min

Filler wire diameter: Min. 0,6 mm – Max. 1,2 mm (standard spool)

Connecting cable: L = 8 m (Others on request)

Feeding Voltage: 24 Vdc

For more information

Contact us

Our border is the world

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency