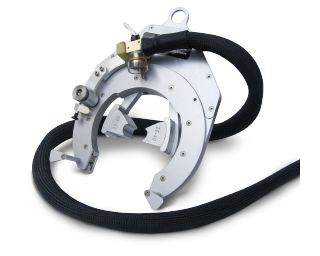

AUTOMATIC ORBITAL WELDING HEAD FOR TUBE TO TUBE

Mod. 211s

OPEN CHAMBER HEAD

(with filler wire)

TECHNICAL CHARACTERISTICS COMMON TO ALL MODELS

Welding procedure: TIG (also with filler wire optional)

Welding position: Horizontal, vertical, inclined

Welding head positioning: By means of adjustable clamps

Torch centering: By elastically mounted clamps and micrometrical screw of axial adjustment ± 2,5 mm

Torch cooling: Gas/water

Torch inclination: Inclined 45°/90°

Electrode diameter: 1 ÷ 3,2 mm (2,4 std)

Front electrode encumbrance: 20

Welding current: 170 A DC MAX

Electrode-to-work distance adjusting: By round tracer and linear radial movement

Connecting cable: L = 8 m

Supply voltage: 24 V DC

OPTIONAL

Filler wire feeding unit: Floor mounted (optional)

Filler wire speed: 10 ÷ 200 cm/min

Filler wire spool: 5 Kg

Filler wire diameter: 0,8 ÷ 1 mm

TECHNICAL SHEET

Welding diameter: 10 ÷ 76,2 mm

Machine weight: 3 Kg

For more information

Contact us

Our border is the world

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency