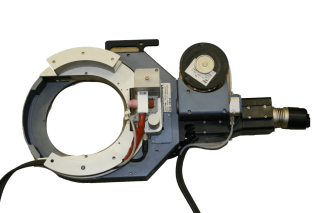

AUTOMATIC ORBITAL WELDING HEAD FOR TUBE TO TUBE

Mod. 214.01

ORBITAL WELDING HEAD WITH AVC AND TORCH OSCILLATION SYSTEMS

(with filler wire)

GENERAL TECHNICAL SHEET

(on request also without filler wire)

WELDING PROCEDURE: TIG with filler wire

WELDING POSITION: Horizontal, vertical, inclined

WELDING DIAMETER: Up to 168,3 mm

WELDING HEAD POSITIONING: Suspended by spring tool balancer

TORCH CENTERING: By elastically mounted clamps and micrometrical screw axial adjustment (± 5 mm)

TORCH COOLING: Water cooled

TORCH INCLINATION: 90° (Others at request)

ELECTRODE DIAMETER: 1 ÷ 3,2 mm (2,4 std)

FRONT ELECTRODE ENCUMBRANCE: 21 ± 5 mm

WELDING CURRENT: 170 A DC max pulsed/linear

ELECTRODE-TO-WORK DISTANCE ADJUSTING: Automatic with AVC

SUPPLY VOLTAGE: 24 V DC

FILLER WIRE FEEDING UNIT: Directly mounted on machine body

FILLER WIRE SPEED: 10 ÷ 200 cm/min

FILLER WIRE MOTOR: Standard, 24 V DC (optional tachofeedback)

FILLER WIRE SPOOL: Standard Midget type Ø 4”about 100 mm

FILLER WIRE DIAMETER: 0,6 ÷ 1,2 mm

CONNECTING CABLE: L = 8 m ; 4,100 Kg

MACHINE WEIGHT: 12,500 Kg

For more information

Contact us

Our border is the world

OPERATING OFFICE

Via Alessandro Dudan n.16/c

00143 ROMA

ITALY

SHOWROOM – TEST AREA

EsseBi WELDING – Via Cà Magre, 23

37063 Isola della Scala (VR)

© 2023 Stelin S.r.l. All rights reserved. P. IVA 08540001008 Privacy Policy Cookie Policy powered by Web Agency